What Size Circuit Breaker Do I Use For My 230 Volt Red Lion Well Pump Motor

How much power does my submersible well pump employ?

Many of our customers and blog readers have been looking for alternative ways to go along their well pump equipment running during power outages. Our blog about sizing generators correctly has been a search engine hitting, but nosotros only went over the nuts of determining what size pump yous have in that commodity. What if you don't know what size pump you have to cull the right generator? In this weblog we'll dive in deep to aid you find how many horsepower, how much current/amperage your pump uses and how many watts of power it consumes while running.

Submersible and above ground pumps take a label on them, at least when they are make clean and new. This characterization has data like how many horsepower or kilowatts the motor is rated for, how many amps the motor is expected to use and the voltage that the pump needs to run properly. Finding this characterization on the above basis pump is usually the work of merely a few seconds, but what about the submersible pump? It is frequently located hundreds of feet in the ground!

Submersible pumps typically have a control box that the wires from the well connect to. This control box will typically take the label on the outside, nonetheless some manufactures or pump installers volition put detailed information inside. To view inside labeling, yous may demand a screwdriver to remove the control box cover. It is advised to shut off the power to the pump before removing any electrical covers and practice appropriate electrical safety measures when working with any electrical devices. If your submersible well pump does not employ a control box & pressure switch and, instead, uses a variable frequency or abiding pressure controller the information, bank check out our more recent blog specifically addressing the generator size for residential pump systems that use VFD controllers.

If you can't find the characterization, don't get frustrated because there are still a few things you can do to find out how big your pump is, or at least go an idea of how large it is. If you lot know the contractor that installed the submersible well pump, give them a call! More than likely they volition have a copy of the invoice that volition show how many horsepower, what size wire, pipe and how deep the pump is. Become this information and hang on to information technology! These are vital pieces of info when (not if) yous need to replace the pump in the future and information technology will help you determine how much power the pump needs if you are looking for a generator.

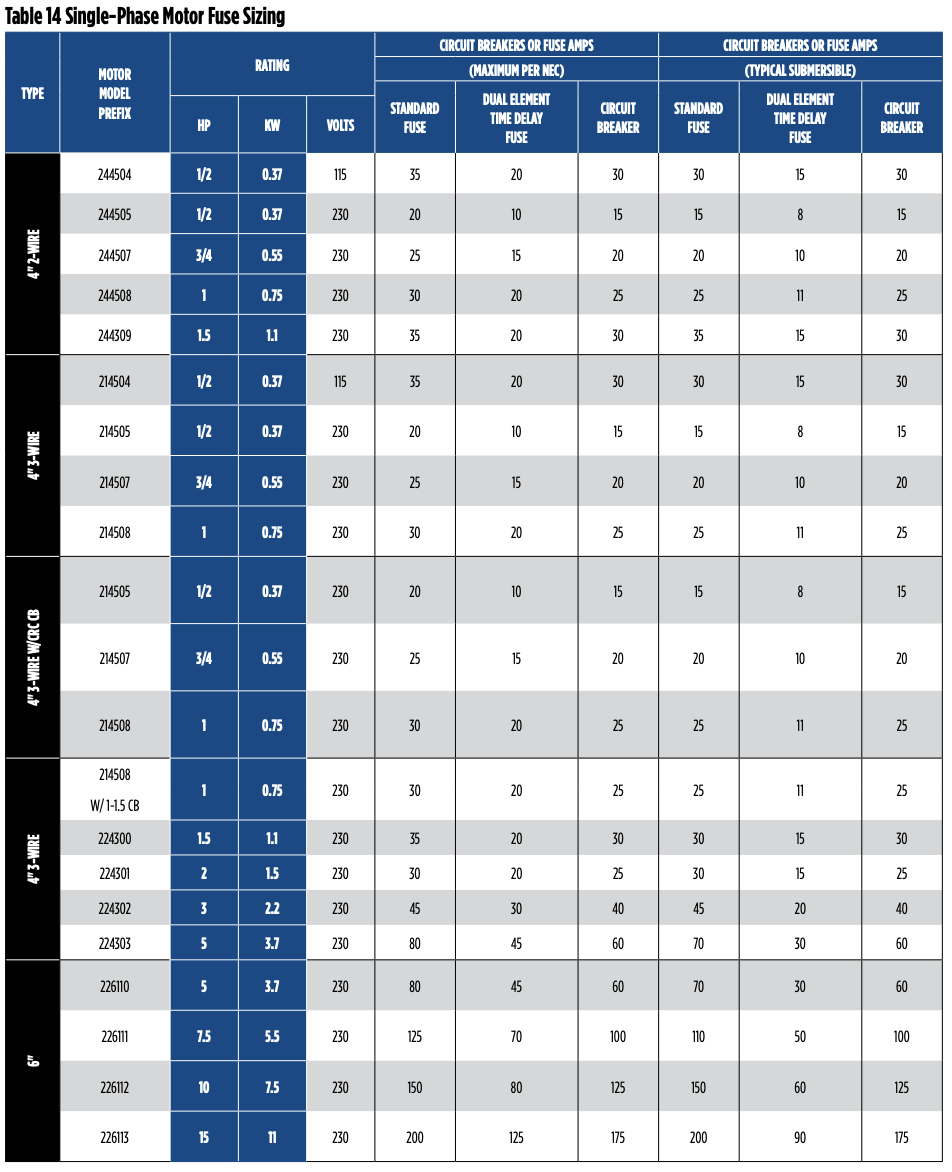

If you don't know who installed the well pump and don't take whatsoever past invoices or records, locate the defended circuit breaker for the well pump. Nigh submersible well pumps are single stage 230 volts and require a two pole circuit billow (ii individual circuit breakers connected together). What amperage rating does the circuit billow indicate? This chart volition help you determine the maximum size pump installed if the installer complied with the national electrical code and Franklin AIM Transmission recommendations/specifications on tables 5 & 14. Please keep in heed that these recommendations are for traditional pump equipment that use a control box/force per unit area switch and large pressure tank.

A general summary of circuit breaker sizes and Generator sizes for various 230 volt pumps are every bit follows:

A xv amp excursion breaker means the pump is smaller than .v hp and volition utilise ~v amps/700 watts during operation and will require at least 1.2 KW internally regulated generator to beginning/operate the pump.

A 20 amp circuit breaker ways the pump is smaller than .75 hp and will use ~eight amps/1100 watts during operation and require a ii KW internally regulated generator to outset and operate the pump. (ane HP pumps are sometimes run on a twenty amp breaker depending on the installer and wire size available)

A 25 amp circuit breaker means the pump is 1 HP or smaller and volition utilize ~9 amps/1400 watts during performance. A 1 HP submersible well pump will require a 2.5 KW internally regulated generator to operate the pump.

A 30 amp breaker means the pump is smaller than 2 hp will use ~13 amps/2300 watts during operation and will require a 4 KW internally regulated generator to operate the pump. (This size billow is also used for 1.5 HP pumps which crave a iii KW internally regulated generator for proper pump operation.)

A xl amp breaker means the pump is smaller than 3 hp will use ~16 amps/3200 watts during operation and require a 5 KW internally regulated generator for proper pump operation.

A 50 amp billow means the pump is smaller than v hp and volition use ~25amps/5300 watts during operation and require a 7.five KW internally regulated generator for proper pump operation.

Did you NOTICE that the circuit breaker is significantly larger than the amount of current/amperage the pump uses during operation? This is not a typo or fault! The circuit breaker needs to be significantly larger considering the amount of current/power used to start the pump spinning/pumping is very loftier. Once the pump has finished accelerating to speed, the current and ability usage will drop down to the normal range. For this same reason you need to size the generator for the starting electric current (circuit billow size) and not the running current of the pump! Check out more than data on page 5 of the AIM Manual or check out our blog if yous desire more info virtually sizing a generator for your submersible well pump.

If y'all are exceptionally astute, you lot will notice that a 1 HP pump uses 1400 watts and yous'll scratch your head trying to make this jive with the 946 watts that your high school physics class taught yous is equivalent to 1 HP. Why the difference? Pumps are rated by the usable piece of work that they perform after all the electric and mechanical inefficiencies accept been lost. The pump may produce i HP/946 watts of usable water flow/pressure, but the actual amount of power required to exercise this is a bit college due to the inefficiencies. Selecting the correct pump for your well can help maximize efficiency AND decrease the capital expenditure for replacement equipment - check out our blog on this topic to acquire about how to choose the most efficient pump for your application, it can save you coin upward front and in the long run!

At present, let'south say you can't locate the excursion billow for your pump and yous oasis't been able to observe the characterization/it is illegible and yous don't have any records about the pump. What to exercise? If this is your situation y'all may want to call a professional person and accept them come up take some basic electrical measurements including winding resistance and actual pump run current (amperage). This will give you a very proficient idea what size pump is in the well and how much power it uses. A professional in our area is going to charge ~$200 to travel to your house, accept the readings and perform a few more checks on your pressure level tank and pressure switch then give you lot an thought of what is going on and make suggestions about annihilation unusual.

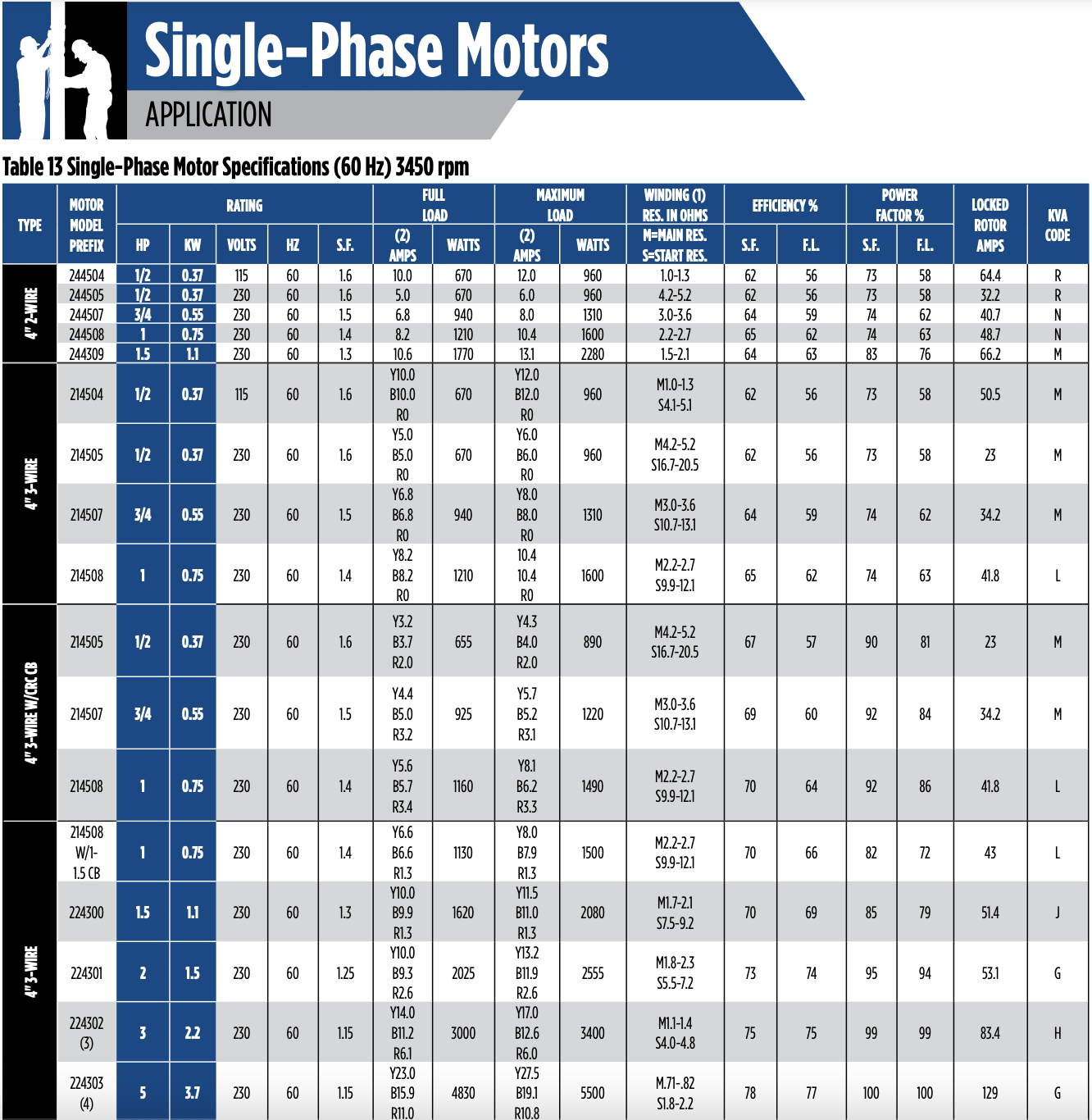

If you lot are handy and accept knowledge and preparation tow piece of work safely with electricity and electrical components, this is something that you lot can practise yourself with a few pointers. Invest the coin you would have spent on a service call into a decent multimeter like the Fluke T6-600. Next, shut off the power to your pump and pull up the reference charts from Tabular array 13 of the Franklin AIM Manual (also shown at the bottom of this web log) Now, locate the power cable to the submersible well pump, it should have 4 colored wires: Ruby-red, Yellowish, Black and Light-green. Switch the T6-600 to the "A" setting and then slide the yellow forks at the top of the meter over the yellow wire. Keeping your easily clear of all electrical equipment and wires turn on the power! At present run some water until the pump turns on and accept note of the amperage reading and compare information technology to the Table thirteen! If yous accept only three wires going to your submersible well pump and there is no command box, and so just mensurate the amperage on either of the non-green wires and compare the reading to the advisable chart in the Franklin Manual for 2 wire motors (not very common). Ensure that you plough the power off and reinstall whatsoever electrical covers, then turn the power back on when you're finished.

If you want to double bank check and you lot have a 4 wire motor, close the power off to the well pump, disconnect the yellow, black and red wires from where they are connected, switch the T6-600 to the Omega sign (for resistance readings in ohms) and touch on the crimson/black tester leads to the blackness and xanthous wires that lead to the pump and write the number downwardly. This is the chief winding resistance (M). Now touch the cherry-red/black tester leads to the red and xanthous wires that pb to the pump and write the number down. This is the start winding resistance (South). Compare these resistance readings to the readings constitute in Table 13 of the Franklin AIM Manual and then carefully reconnect the wires the way you plant them and turn power back on to the pump equipment. Y'all should accept a very precise idea of what size pump is in your well. Write the information down and keep it in a handy place! Make sure y'all put the wires back where you institute them and plough the power back on or y'all won't accept any water. Refer to figure 11 in the Franklin AIM transmission for additional instructions on this procedure.

Our professional squad at Oakville Pump Service helps our clients from Napa, Calistoga, Pope Valley and everywhere in between equally they keep the h2o flowing to businesses, homes and agriculture. Give u.s.a. a telephone call today (707) 944-2471 if we can help solve your water related problems!

Please note that Amazon links have been provided to show illustrations of products mentioned in this web log. These links are not intended to show the exact product for your specific awarding, rather a generic visual example of the product referenced. While purchasing these items is possible, delight practise so after having done your ain due diligence and understand that these links may generate Amazon commissions. If you lot practise not have a through understanding of proper electrical safety procedures, then you should not try working with the electric equipment mentioned in this blog as it represents a significant hazard of electric shock and personal injury.

What Size Circuit Breaker Do I Use For My 230 Volt Red Lion Well Pump Motor,

Source: https://oakvillepump.com/blog/2021/3/17/how-much-power-does-my-submersible-well-pump-use#:~:text=Most%20submersible%20well%20pumps%20are,individual%20circuit%20breakers%20connected%20together).

Posted by: nicholscappereen.blogspot.com

0 Response to "What Size Circuit Breaker Do I Use For My 230 Volt Red Lion Well Pump Motor"

Post a Comment